+91-9912355536

support@dentxmart.com

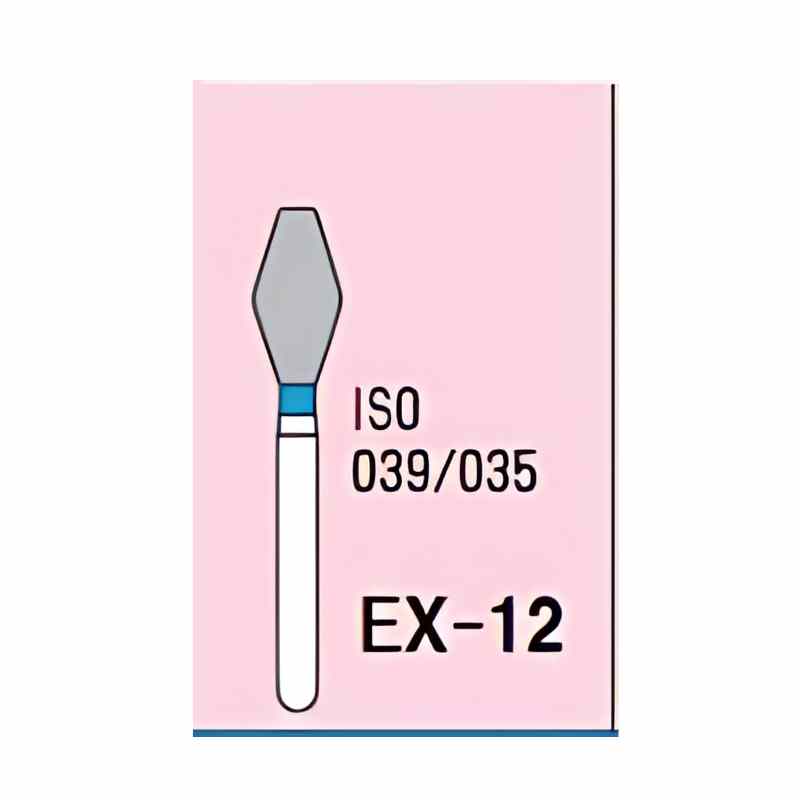

Mani Diamond Burs – Special (Extra) Shape / Ex Series

Diamond-coated dental burs designed for accurate cavity preparation, delivering superior results in dental treatments.

₹400.00 Original price was: ₹400.00.₹280.00Current price is: ₹280.00.

MRP Inclusive of all taxes

Buy more save more!

Buy from 5 to 10 items and get 1% OFF

on each productBuy from 11 to 20 items and get 2% OFF

on each product- Free shipping on all orders above Rs. 2,500

- No hassle returns, 10 days return

- Express delivery all over India

Product Details

Mani Diamond Burs are high-precision dental tools designed with a stainless steel working part that is coated with fine diamond crystals. These rotary grinding instruments are specifically crafted to handle precision work on hard tissues such as teeth and bones, which makes them essential in modern dentistry.

Compatible with dental handpieces, these burs offer controlled and efficient use during a variety of dental procedures, ensuring optimal performance and accuracy. Whether it’s for cavity preparation, crown shaping, or other intricate dental tasks, they provide the reliability dental professionals need.

In addition to their primary use in dentistry, Mani Diamond Burs are highly versatile and can also be employed in grinding other hard materials like metals, plastics, and porcelain. This adaptability makes them valuable tools not only in dental practices but also in industrial and laboratory environments where precise material removal is crucial.

The fine diamond crystal coating on these burs guarantees exceptional durability and longevity. This ensures that they maintain consistent performance over time, making them a dependable choice for professionals seeking precision, reliability, and efficiency in their work.

Features

- This product is designed to be attached to a dental handpiece, where it rotates to efficiently grind hard materials and tissues. It is a dental diamond bur with a stainless steel shank and is a non-sterile instrument.

- Key materials include: a) Metal Base: Stainless steel, which may include nickel and chromium. b) Working Part: Fine diamond crystals bonded to the metal base, incorporating nickel and chromium. c) Shank: Stainless steel, which also contains nickel and chromium.

Specifications

- A diverse range of diamond burs, with each code representing the bur’s specific shape.

- Metal base made of stainless steel.

- Fine diamond crystals bonded to the metal base for effective cutting performance.

Package Contents

- Pack of 5 Burs

Directions To Use

Prepare the Work Area:

Ensure that the work area is clean, organized, and ready for use. Make sure all necessary dental instruments and materials are readily available.

Select the Right Bur:

Choose the Mani Diamond Bur that best suits the specific dental procedure in terms of shape, size, and grit.

Shank Insertion:

Carefully insert the shank of the Mani Diamond Bur into the dental handpiece, ensuring a secure and stable connection.

Pre-Use Inspection:

Before use, run the bur at a low speed to check for any signs of wobbling or misalignment. If any irregularities are detected, replace the bur to ensure optimal performance.

Prepare the Patient:

Ensure the patient is comfortably positioned and adequately anesthetized, if necessary, before proceeding with the dental procedure.

Coolant and Lubrication:

During the procedure, consistently use coolant spray to prevent the bur and treated area from overheating. Ensure a steady water supply to avoid blockages and reduce the risk of pulp-related complications.

Apply Proper Pressure and Speed:

Apply the appropriate pressure, typically between 20 and 50 PSI, depending on the size of the bur. Operate the bur within its recommended RPM range to ensure efficiency and prevent overheating.

Use Correct Motion:

Maintain smooth, controlled movements throughout the procedure. Avoid sudden motions such as levering, tilting, twisting, or jamming, as they can affect the precision of the work. Never apply a pulling motion, as it could damage both the instrument and the procedure outcome.

Sterilization:

Once the bur has been used, clean and sterilize it thoroughly to maintain hygiene and ensure it is ready for future use.