+91-9912355536

support@dentxmart.com

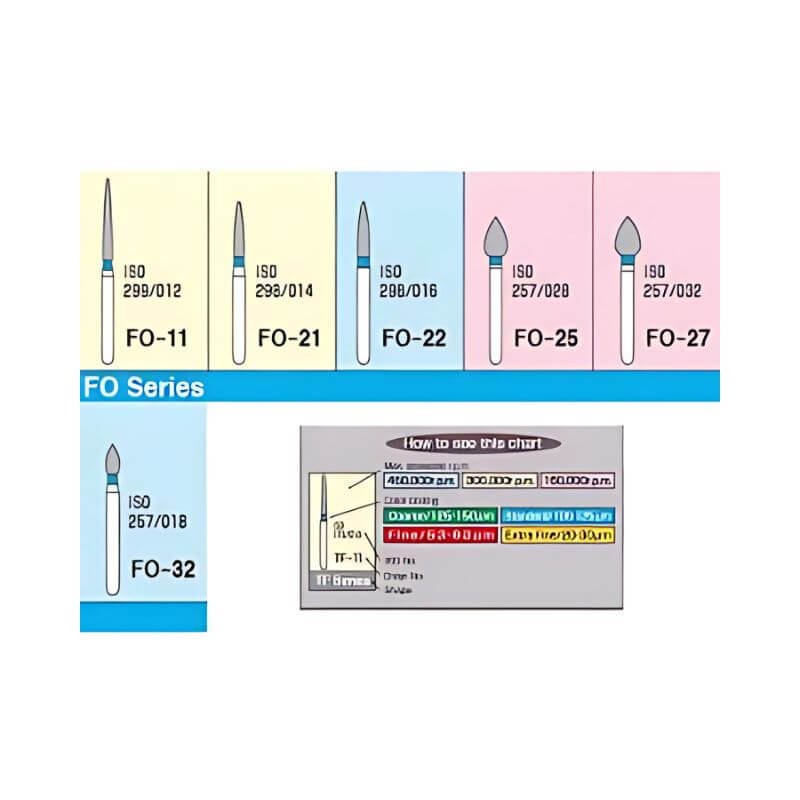

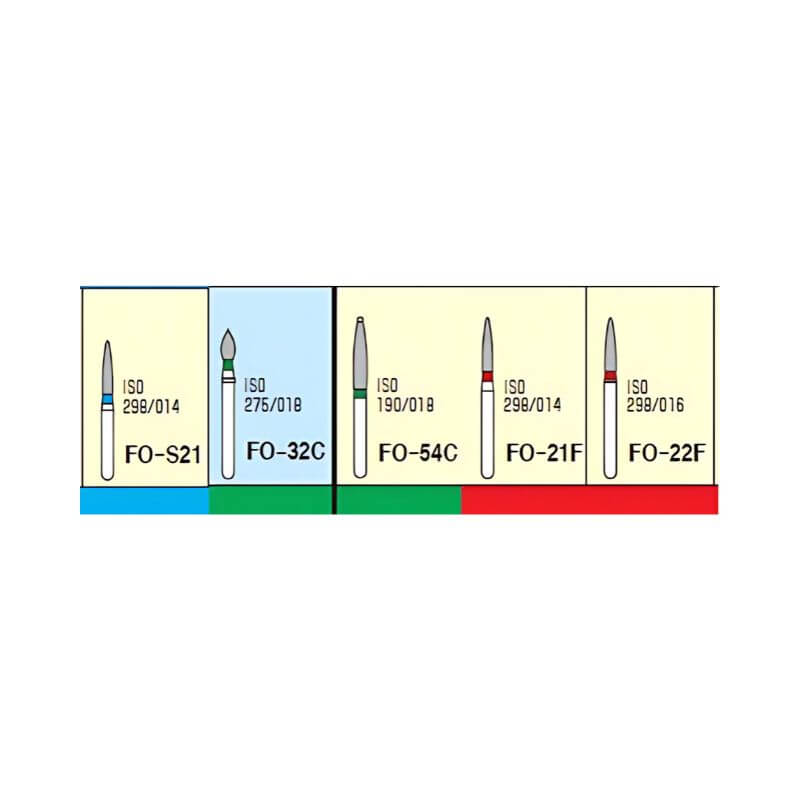

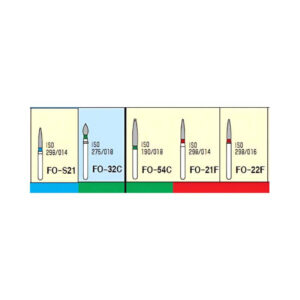

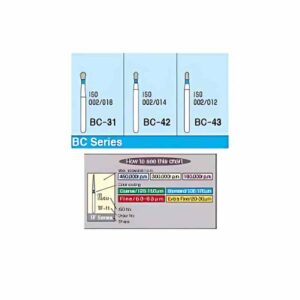

Mani Diamond Burs – Flame Ogival End / Fo Series

Diamond-coated burs designed for precise cavity preparation, ensuring accuracy and efficiency in dental procedures.

₹430.00 Original price was: ₹430.00.₹280.00Current price is: ₹280.00.

MRP Inclusive of all taxes

Buy more save more!

Buy from 5 to 10 items and get 1% OFF

on each productBuy from 11 to 20 items and get 2% OFF

on each product- Free shipping on all orders above Rs. 2,500

- No hassle returns, 10 days return

- Express delivery all over India

Product Details

Mani Diamond Burs are high-precision dental tools with a stainless steel core coated in fine diamond crystals. These rotary grinding instruments are specifically designed for working on hard tissues like teeth and bones, making them essential in dentistry. They seamlessly integrate with dental handpieces, enabling precise and efficient operation during various dental treatments.

Beyond dental applications, these burs are versatile and suitable for grinding a variety of hard materials, including metals, plastics, and porcelain. Their durability and fine diamond coating make them a reliable choice not only for dental professionals but also for industrial and laboratory settings requiring precise material removal. Designed for longevity, they ensure accuracy and efficiency in every use

Features

Reliable & Tested: Undergoes rigorous quality control to ensure performance and durability.

High Precision Cutting: Designed for accurate and efficient grinding of hard tissues and materials.

Minimal Debris Generation: Reduces debris buildup for a cleaner working environment.

Versatile Application: Suitable for sectioning multi-rooted teeth and grinding various materials like metal, plastic, and porcelain.

Durable Construction: Made with a stainless steel shank and a fine diamond-coated working part for long-lasting use.

Seamless Compatibility: Designed for use with dental handpieces, ensuring stable rotation and efficient operation.

Specifications

- Bur Variety: Available in multiple shapes, each identified by a unique code.

- Material Composition: Stainless steel base with fine diamond crystal coating for durability.

- Shank Material: High-quality stainless steel for strength and stability.

- Shank Type: Friction grip for a secure fit in dental handpieces.

- Shape: Tapered conical design for precise cutting and grinding.

- Working Part: Diamond-coated surface for efficient and smooth performance.

Package Contents

- Pack of 5 Burs

Directions To Use

Handpiece Compatibility

- Use a dental handpiece that securely holds the shank.

- Ensure proper fit based on shank type:

- Friction Grip Shank: 1.6mm diameter

- Contra-Angle Shank: 2.35mm diameter

- Use a handpiece that allows speed control and has a water spray system.

Work Area Preparation

- Maintain a clean and well-organized workspace.

- Ensure all required dental instruments and materials are ready for use.

Bur Selection & Insertion

- Choose the appropriate Mani Diamond Bur based on shape, size, and grit.

- Fully insert the shank into the dental handpiece for a stable connection.

Pre-Use Inspection

- Run the bur at a low speed to check for any wobbling or imbalance.

- If defects are found, replace the bur to ensure precise operation.

Patient Preparation

- Ensure patient comfort and administer anesthesia if necessary.

Cooling & Lubrication

- Use continuous water spray during operation to prevent overheating.

- Maintain proper coolant flow to avoid clogging and minimize pulp-related risks.

Optimal Speed & Pressure

- Apply controlled pressure (typically 20–50 PSI) based on bur size.

- Operate within recommended RPM limits to maintain efficiency and prevent overheating.

Proper Handling

- Maintain steady, controlled motions during the procedure.

- Avoid abrupt tilting, twisting, or excessive force that could damage the instrument.

- Do not use a pulling motion to ensure precision and longevity.

Sterilization & Maintenance

- Thoroughly clean and sterilize the bur after each use to ensure hygiene and durability.