+91-9912355536

support@dentxmart.com

Mani Diamond Burs – Extra Fine / Ef Series

Diamond-coated dental burs designed for accurate cavity preparation, guaranteeing superior outcomes in dental treatments.

₹415.00 Original price was: ₹415.00.₹280.00Current price is: ₹280.00.

MRP Inclusive of all taxes

Buy more save more!

Buy from 5 to 10 items and get 1% OFF

on each productBuy from 11 to 20 items and get 2% OFF

on each product- Free shipping on all orders above Rs. 2,500

- No hassle returns, 10 days return

- Express delivery all over India

Product Details

Mani Diamond Burs are specialized dental tools featuring a stainless steel working surface coated with fine diamond crystals. These rotary grinding instruments are designed for high-precision work on hard tissues such as teeth and bones, making them essential in dental procedures.

Compatible with dental handpieces, they allow for controlled and efficient operation during various treatments. Beyond their primary use in dentistry, Mani Diamond Burs are versatile and can also be used for grinding a variety of other hard materials, including metals, plastics, and porcelain. This makes them valuable not only in dental practices but also in industrial and laboratory environments where precise material removal is crucial.

The fine diamond coating enhances their durability and ensures long-lasting performance, making them a dependable choice for professionals seeking precision and efficiency in their work.

Features

Precision Cutting: Engineered for precise and controlled cutting, making them perfect for delicate dental procedures and adjustments.

Smooth Finishing: The ultra-fine grit ensures a smooth finish on tooth surfaces, reducing the need for additional polishing.

Durability: Built with high-quality materials for long-lasting use and resistance to wear, maintaining effectiveness over multiple uses.

Versatile Application: Ideal for various tasks, including cavity preparation, crown and bridge work, and finishing composite restorations.

Efficient Performance: Designed for optimal cutting efficiency, shortening chair time and enhancing workflow in dental practices.

Comfortable Handling: Ergonomically crafted for ease of use, minimizing hand strain during prolonged procedures.

Heat Resistance: Designed to reduce heat build-up during use, safeguarding the dental pulp and surrounding tissues.

Specifications

Type: Diamond burs made especially for dental work.

Grit: Extra fine (EF) grit is perfect for finer details and smoother finishing.

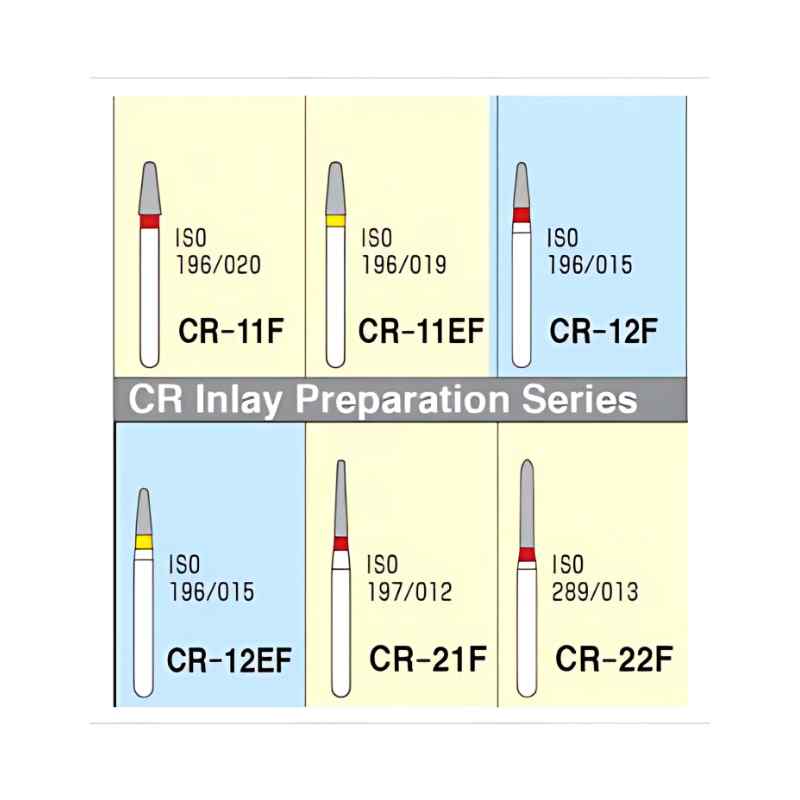

Size Options: Available in a range of sizes and shapes, including tapered, flat, and round, to suit various dental procedures.

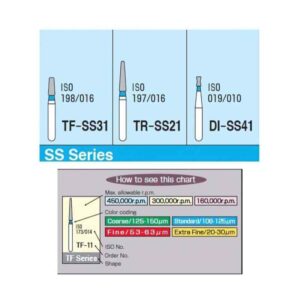

Shank Size: Usually fits standard handpieces; the ISO standard shank size is 1.6 mm.

Material: Made from premium diamond particles adhered to a sturdy metal foundation for effective cutting.

Packaging: To guarantee safety and hygienic use in clinical settings, it is typically supplied in sterile packaging.

Package Contents

- Pack of 5 Burs

Direction to Use

Set Up the Work Area:

- Ensure the workspace is tidy and well-organized.

- Have all the necessary dental instruments and materials prepared and within reach.

Choose the Correct Bur:

- Select the appropriate Mani Diamond Bur based on the required shape, size, and grit for the specific dental procedure.

Insert the Shank:

- Securely place the shank of the Mani Diamond Bur into the dental handpiece, ensuring a stable and proper connection.

Inspect Before Use:

- Prior to use, operate the Mani Diamond Bur at a low speed to check for any wobbling or misalignment. If any issues are detected, replace the bur to maintain accuracy.

Prepare the Patient:

- Ensure the patient is comfortable and appropriately anesthetized, if needed, before proceeding with the dental treatment.

Use Coolant and Lubrication:

- Continuously apply coolant spray during the procedure to prevent the bur and treated area from overheating.

- Maintain a consistent water supply to prevent clogging and reduce the risk of potential pulp damage.

Maintain Proper Pressure and Speed:

- Use the correct pressure, generally between 20 to 50 PSI, based on the bur’s diameter.

- Operate the bur within the specified RPM range to avoid overheating and maintain optimal performance.

Proper Technique:

- Keep movements steady and controlled during the procedure, avoiding any sudden or excessive motions like levering, tilting, twisting, or jamming.

- Never pull the bur, as this can cause damage to the instrument and reduce the accuracy of the procedure.

Post-Procedure Cleaning and Sterilization:

- After the procedure is completed, clean and sterilize the bur properly to prepare it for future use.