+91-9912355536

support@dentxmart.com

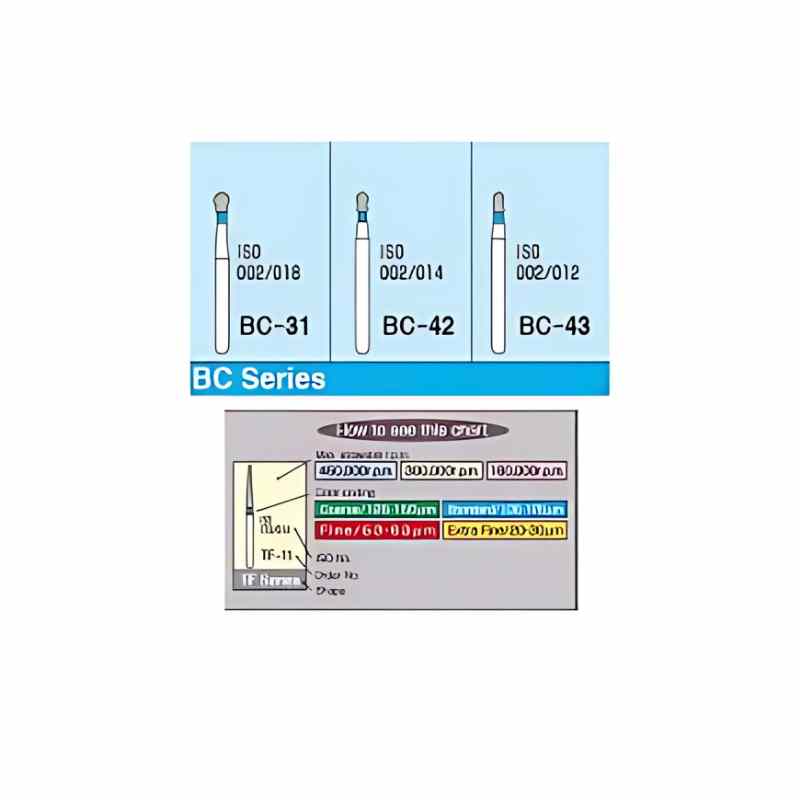

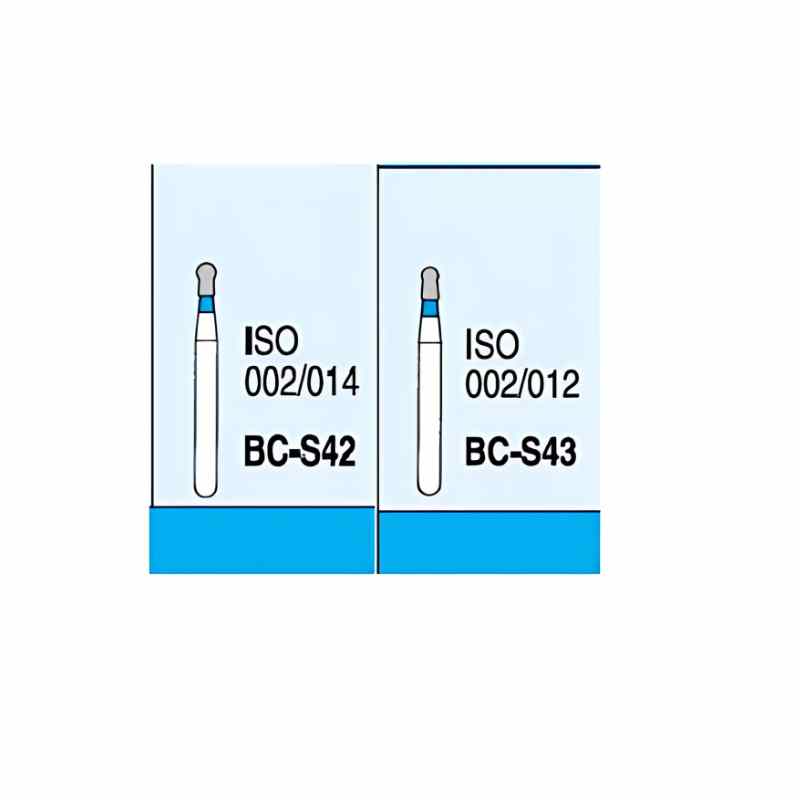

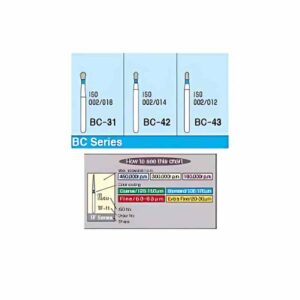

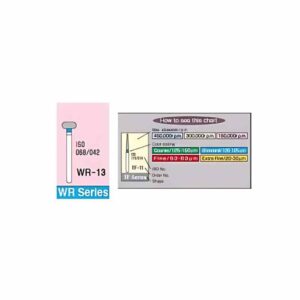

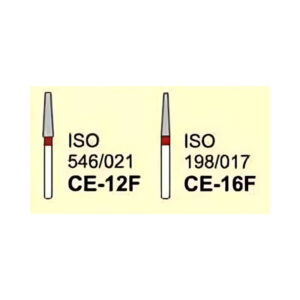

Mani Diamond Burs – Ball Collar Type / Bc Series

Diamond-coated dental burs designed for accurate cavity preparation, delivering excellent outcomes in dental procedures.

₹400.00 Original price was: ₹400.00.₹280.00Current price is: ₹280.00.

MRP Inclusive of all taxes

Buy more save more!

Buy from 5 to 10 items and get 1% OFF

on each productBuy from 11 to 20 items and get 2% OFF

on each product- Free shipping on all orders above Rs. 2,500

- No hassle returns, 10 days return

- Express delivery all over India

Product Details

Mani Diamond Burs: Specialized Dental Instruments

Mani Diamond Burs are precision dental tools designed with a stainless steel working part coated with fine diamond crystals. These rotary grinding instruments are expertly crafted for precision work on hard tissues such as teeth and bones, making them essential in dental practices. Their fine diamond coating enables smooth and efficient cutting, ensuring excellent results in a variety of dental procedures.

Versatile Applications in Dentistry and Beyond

These dental burs are compatible with standard dental handpieces, offering controlled and efficient use during procedures like cavity preparation, crown work, and other restorative tasks. Mani Diamond Burs are also versatile enough to be used for grinding a wide array of hard materials beyond dental applications. This includes metals, plastics, and porcelain, making them valuable tools not only in dentistry but also in industrial and laboratory settings that require precise material removal.

Durability and Reliability

The diamond crystal coating on these burs ensures enhanced durability and long-lasting performance, providing dental professionals with a reliable instrument for achieving accurate and efficient results. Whether performing intricate dental procedures or working with various hard materials, Mani Diamond Burs are trusted tools that maintain precision throughout their use.

Features

- Durable diamond burs with extended lifespan

- Rigorously tested for quality assurance

- High precision and effective cutting performance

- Ideal for cutting procedures with minimal debris

- Suitable for grinding applications

- Perfect for sectioning multi-rooted teeth and reducing crown height

- Premium quality diamond burs

- Provides efficient and consistent cutting results

Specifications

- Shank Composition: Made from stainless steel

- Shank Design: Friction grip type

- Shape: Ball collar

- Working Surface: Fine diamond crystals bonded to the metal base

- Compatibility: Suitable for use with all standard air rotors available in the market

Package Contents

- Pack of 5 Burs

Directions To Use

Work Area Setup:

- Ensure the workspace is clean and well-organized.

- Have all necessary dental tools and materials readily available.

Selecting the Correct Bur:

- Choose the appropriate Mani Diamond Bur based on shape, size, and grit suited to the procedure.

Inserting the Bur:

- Securely insert the shank of the Mani Diamond Bur into the dental handpiece, ensuring a stable connection.

Inspection Before Use:

- Run the bur at low speed to check for any wobbling or misalignment. If any irregularities are found, replace the bur to maintain precision.

Preparing the Patient:

- Make sure the patient is comfortable and appropriately anesthetized, if necessary, before beginning the procedure.

Coolant and Lubrication:

- Use a continuous coolant spray during the procedure to prevent overheating of both the bur and the treated area.

- Ensure a consistent water flow to avoid clogs and minimize the risk of pulp complications.

Correct Pressure and Speed:

- Apply the recommended pressure, typically between 20 to 50 PSI, based on the bur’s size.

- Operate the bur at or below the recommended RPM to prevent overheating and ensure effective cutting.

Maintaining Proper Technique:

- Perform the procedure with steady, controlled movements, avoiding abrupt motions like levering, twisting, or jamming.

- Refrain from pulling motions, as this can damage both the instrument and the precision of the procedure.

Post-Procedure Care:

- Clean and sterilize the bur thoroughly after use to prepare it for future use.