+91-9912355536

support@dentxmart.com

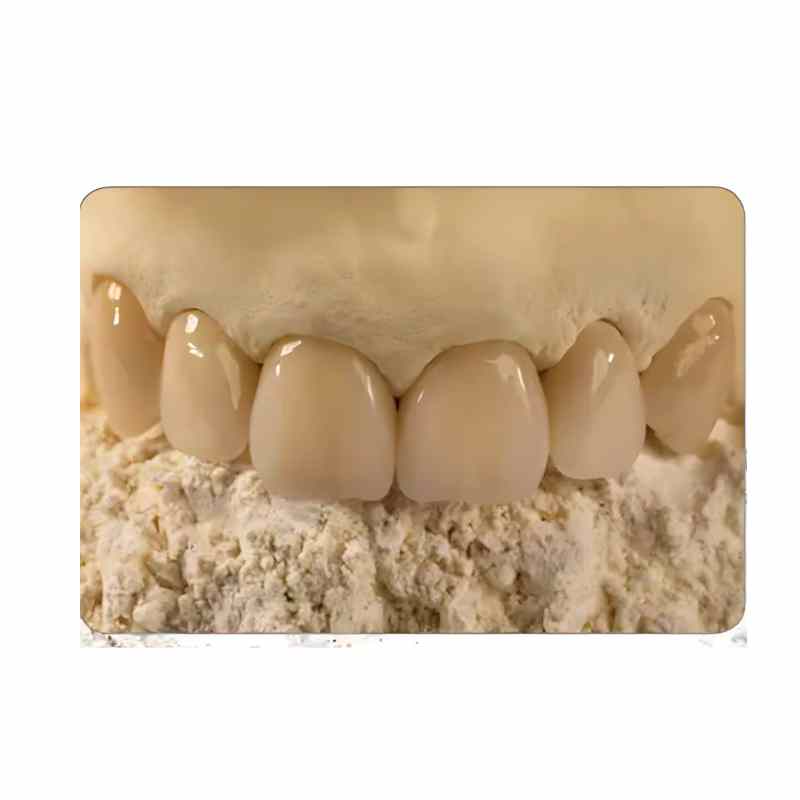

GC Fuji Rock Ep Golden Brown 5kg

Improved Type 4 Dental Stone

₹2,010.00 Original price was: ₹2,010.00.₹1,820.00Current price is: ₹1,820.00.

MRP Inclusive of all taxes

Buy more save more!

Buy from 3 to 10 items and get 2% OFF

on each product- Free shipping on all orders above Rs. 2,500

- No hassle returns, 10 days return

- Express delivery all over India

Product Details

GC FujiRock EP is a premium dental stone that delivers exceptionally smooth and fine dies, as well as accurate working and study models. As a Type IV Dental Die Stone, it is perfect for a variety of prosthetic applications, offering high precision, excellent edge hardness, and superior pressure stability. The product features a longer pour time and a faster setting time, resisting chipping and providing high compressive strength. It also minimizes expansion and delivers a hard, glossy surface.

This material is highly fluid while maintaining thixotropic properties, making it easy to handle and pour without trapping air bubbles. Its high-pressure stability ensures a perfect fit for prosthetics right from the start.

Indications:

- Ideal for producing a wide range of prosthetics.

- Compatible with various types of impression materials.

Advantages:

- High wettability for easier mixing.

- Fast mixing time for improved efficiency.

- Fluid yet thixotropic for easy pouring and excellent handling without air bubbles.

- Snap set for longer working time and quicker setting.

- Short removal time for faster results.

Features

This material is made from an extremely hard stone, providing superior wear resistance. Its high transverse and compressive strengths significantly reduce breakage and chipping, ensuring greater durability.

With ideal thixotropicity, the formula enables smoother pouring, which helps in reproducing fine details without any dimensional changes. This property ensures accurate and precise results in every application.

The low “powder-water” ratio also means less water is required, contributing to outstanding strength and excellent physical properties.

Formulated specifically for high accuracy and a precise fit, this material results in fewer remakes, higher quality outcomes, and reliable performance every time.

Specifications

The P/L ratio is 20 mL per 100 g, ensuring the correct consistency for optimal performance. When mixed manually, the process takes just 15 seconds, while vacuum mixing requires between 30 to 60 seconds for the best results.

The material offers a working time and pouring time of 8 minutes, providing ample time for proper handling. The setting time is 12 minutes, allowing enough time for the material to properly cure.

With a setting expansion of only 0.08% (according to ISO standards over 24 hours), this material ensures precise dimensional stability. Additionally, it boasts an impressive compressive strength of 53 MPa, making it highly durable and robust.

Package Contents

- 1 x GC Fujirock Ep 5kg Bucket

Directions To Use

Always use room temperature water, preferably distilled, for mixing. Begin by placing the water into the bowl first, then gradually add the powder to the water in an even manner.

Mix by hand using back-and-forth strokes, occasionally rotating the bowl and scraping down the sides to incorporate any dry, unmixed material. Continue this process until a smooth, creamy, and homogeneous mixture is achieved. Vacuum mixing can also be used as an alternative method for achieving consistency.

Once the mix is ready, pour the stone into the impression and allow it to set. The cast models can be removed from the impressions once the exothermic reaction is complete.